·Numerical control system. Adopt Taiwan (SYNTEC)

system, high stability, high precision.

·High precision spindle. Structure of the built-in

motorized spindle, spindle NSK (Japan) with high precision angular contact ball

bearing, ensure the accuracy of the spindle high rigid and durable properties.

·High rigid bed. Stable structure design, high quality

baking cast iron bed, strong rigidity. High precision of feed. Feed full servo

drive shafts, NSK (Japan) with high precision ball screw bearing, using silver/PMI

(Taiwan) and high precision leadscrew rail, ensure the machining accuracy and

the precision of the long time, feed the repositioning precision shaft &

le;

·Guide sleeve structure. Can choose the fixed guide

bush cutting and transduction of cutting way back, meet a variety of processing

requirements.

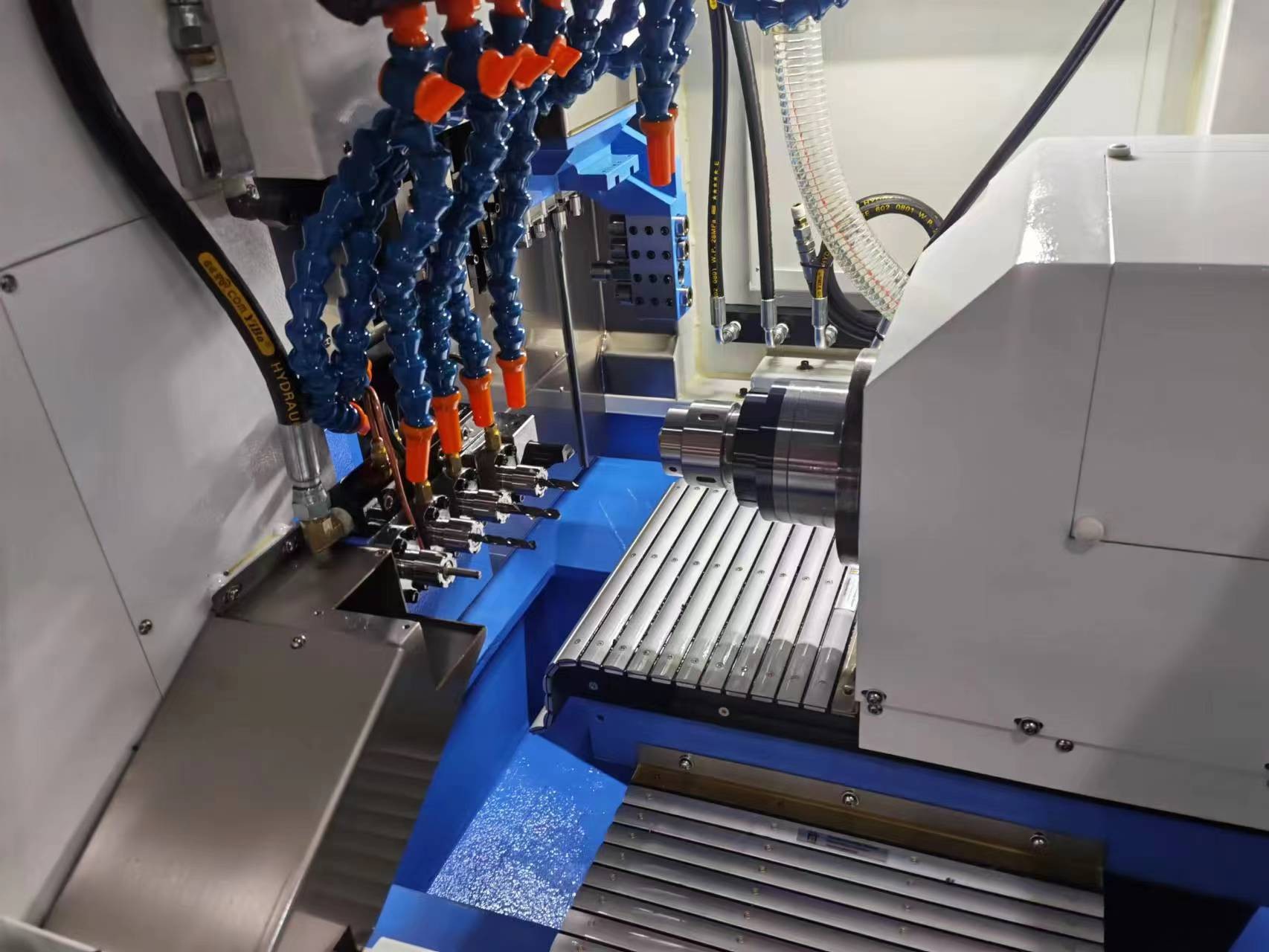

·Knife row structure. Adopted the unbroken type knife

row layout form, compact structure, equipped with side power tool and spindle

dividing function, can satisfy the complex car, milling, drilling composite

processing needs.

·Lubrication system. All screw and guide rail

lubrication centralized lubrication system, guarantee the long-term efficient

operation of machine tool.

·Automation. By configuring the automatic feeder,

automatic continuous processing purposes.

·Widely used in electronics, automobiles, toys,

medical, instrumentation, aerospace and other industries of complex, small,

precise, slender shaft parts processing.

Jiangsu Elite Machinery Co.,Ltd.

Jiangsu Elite Machinery Co.,Ltd.